The handling of materials is essential in the industry, since it is essential to optimize processes, reduce costs and reduce risk. We present the 10 basic principles of material handling to reduce costs and increase the productivity of the industrial plant developed by Material Handling Institute:

Planning Principle

Be clear objectives objectives and functional specifications of the proposed methods.

Standardization principle.

Equipment, controls and software must be standardized within the limits that achieve global performance objectives without sacrificing flexibility, modularity and production.

Work Principle.

Material handling work should be minimized without sacrificing productivity or the required level of operation.

Ergonomic principle.

Human capabilities and limitations must be recognized to ensure safe and effective operations.

Unit Load principle.

The unit loads must be of the appropriate size and be configured according to which they achieve a material flow and the inventory objectives at each stage of the supply chain.

Space Utilization principle.

Effective and efficient use of available space must be made.

System principle.

Material movement and storage activities must be fully integrated to form an operating system that encompasses reception, inspection, storage, production, assembly, packaging, unification, order selection, shipping, transportation, and claims handling.

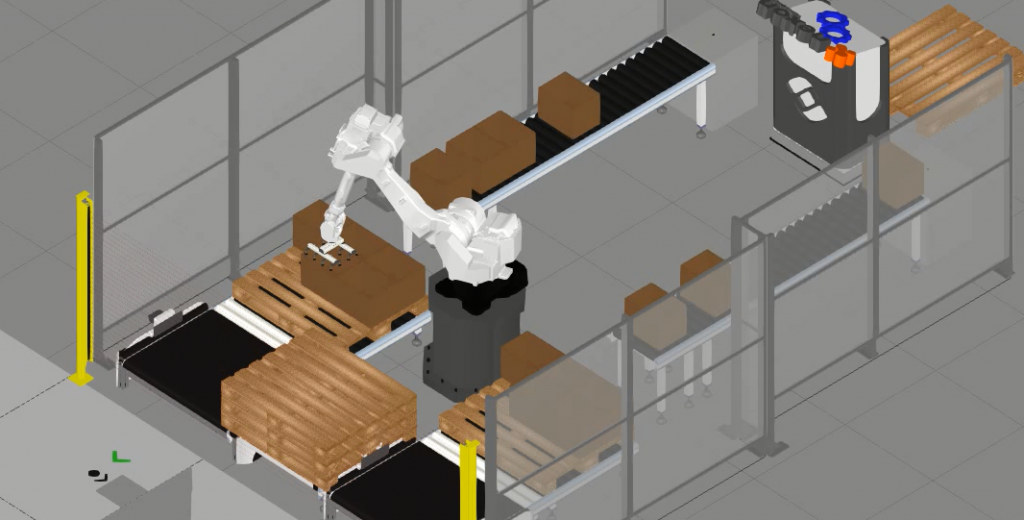

Automation principle.

Material handling operations should be automated where possible in order to improve operational efficiency, increase responses, improve consistency and predictability, and lower operating costs.

If we pay attention to how the industry has changed in the last 20 years, the number of people involved in each of the stages of the process is less and less with new technologies, if it is automated, it gains in reliability, efficiency, safety , time, standardization and transportation, since there is better coordination.

Currently, among the main technologies and solutions that are being used to improve the end of line process, stand out robotized arms systems, automatic palletizing, AGV’s among others.

Environmental principle.

The environmental impact and energy consumption must be considered criteria when selecting equipment for handling materials.

Life cycle cost principle.

Develop a comprehensive economic analysis that takes into account the entire life cycle of material handling systems.

If you want to improve your process of material handling online and end of line, contact us, we are ready to support you.

Do you want to know more about material handling options? Click here